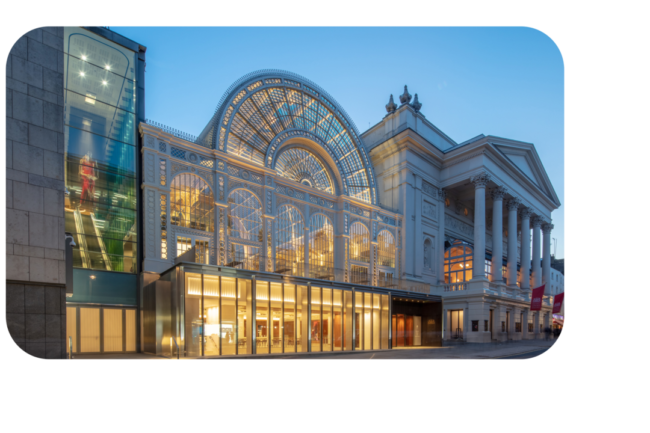

Royal Opera House Covent Garden

The iconic Royal Opera House required comprehensive waterproofing solutions to the stunning new entrance canopy and orchestra pit within the buildings’ basement.

The Challenge

The Royal Opera House in Londons’ Covent Garden is the third theatre built on the Covent Garden site, the previous two having been destroyed by fire in 1808 and 1856. Having undergone several multi-million-pound refurbishments since the current building was opened in 1857, the Royal Opera House has been transformed again during a three year £50.7m transformation that was completed in 2018. The latest works have seen a new intimate performance space created – the Linbury theatre – new airy public spaces with bigger terraces, a café, bar, restaurant, and shop, alongside a new events programme aimed at helping ballet and opera to lose their elitist tags.

The Solution

Cast Contracting ltd were commissioned by Careys to implement waterproofing solutions to the new entrance canopy, comprising GCP Preprufe 300R to the concrete basement slabs and a combination of GCP Biuthene LM and RIW Flexiseal Pro liquid applied systems to the high-level links around the entrance and to the paved areas below.

The challenging nature of waterproofing the new build link extension meant that the works required a complex sequenced waterproofing solution, delivered by the team over 24-hour installation periods, to ensure the strict deadlines for the project were achieved.

In the depths of the building, the orchestra pit required the installation of an internal cavity drain system that would control and eliminate the ingress of water below ground level, whilst strictly adhering to British Standards BS8102:2009 ‘Protection of Below Ground Structures from water from the ground’. GCP’s Hydroduct CF20 cavity drain system was installed to the walls and floors of the pits, including 50mm thick closed cell extruded insulation within the floor build up under the floor membrane. Hydroduct CF channel was installed around the perimeter, linking to suitable drainage including the provision of inspection/jetting ports to allow for future maintenance of the system.

Client Testimonial

“Cast Contracting’s waterproofing expertise ensured that all of the critical waterproofing works carried out at The Royal Opera House were to the highest professional standard. The helpful and proactive team of applicators were able to deliver the waterproofing works to our strict installation programme whilst achieving a high quality of workmanship.”

Tom Ogden, Site Manager, Careys PLC

Products Specified

- GCP Preprufe 300R Plus

- GCP Hydroduct CF20

- GCP Hydroduct CF channel

- GCP Bituthene LM

- RIW Flexiseal Pro

- Protection Board

- Newton Fibran XPS-500C insulation

Design | Supply | Installation

Cast Contracting Ltd (CCL) is the UK’s leading specialist in Design and Installation of all Waterproofing, Tanking and Ground Gas Systems across the United Kingdom. CCL prides itself on offering the highest level of service throughout the Design, Planning, and Installation process.

Structural Waterproofing & Ground Gas Solutions

CCL’s in-house design team can offer a comprehensive proposal for all scenarios in line with BS:8102 and BS:8485.

CCL Guarantees

One of the most comprehensive Guarantees across the industry, taking full project ownership.

Heritage

Cast Contracting Limited is one of the longest standing industry specialists. As it is now part of the CCL Group of Companies, Cast Contracting Ltd has the additional stability and support with over sixty employees across the Group.